Installing tile properly takes skill and experience. When you subcontract this job out, it pays to have quality assurance procedures in place to guard against cracked tile and other defects. Here’s what builders should look out for when assessing the quality of tile work.

Preventing Problems

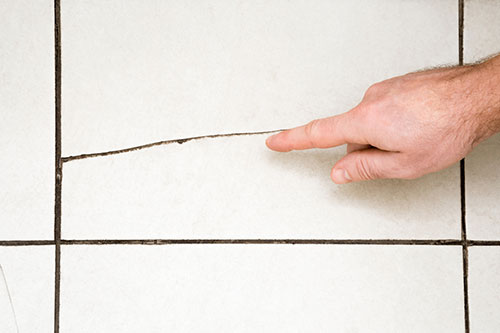

Whenever you bond a rigid material to an underlying surface that moves, cracking is a major concern. When tile is mortared directly to a subfloor, it doesn’t take much to break the mortar’s bond or send cracks spidering through grout lines or the actual tiles. In almost every instance, cracked tiles are a sign of improper preparation of the substrate.

Whether it’s improper isolation of the tile or excessive bounce, everything goes back to the underlying surface. Even the most durable tile will crack if a wood-framed subfloor deflects under pressure. Before adding any underlayment, floor rigidity should be L/360 at minimum, meaning the surface shouldn’t deflect by the span divided by 360. When things fall short of this standard, extra framing can be used to stiffen the surface you plan to have tiled.

With all that said, even the firmest subfloor will move depending on the humidity, temperature and load. The only way to deal with this it to separate the tile from the subfloor. Many contractors will attempt this by laying the tile directly on ¼-inch-thick backer board. This adds stiffness, while creating separation. To further reduce the risk of cracking, however, it’s generally best to use some type of anti-fracture membrane.

Using an Anti-fracture Membrane

Similar to wood floors, tile is much less likely to break if it sits atop an anti-fracture membrane. There are a number of options available, including uncoupling and isolation membranes, synthetic fabrics and liquid-applied coatings. Each option usually works quite well, depending on the underlying surface. Before application, however, you should consider the following:

- Prior to using peel-and-stick or liquid membrane, make sure the humidity does not exceed the manufacturer’s required percentage. You should make sure the contractor drills holes in the slab and inserts a moisture probe to make sure conditions are acceptable before any work begins.

- If there are any hollow-sounding dead spots beneath the tile, it’s likely a sign that moisture has migrated up from the slab and caused the inset mortar to release. The contractor should use a membrane and under-slab vapor barrier to prevent this.

- Since thickness determines quality with liquid-applied membranes, it’s best to have quality assurance procedures ready to ensure that the contractor applies the membrane at recommended thickness. You should also make sure anti-fracture membranes are installed continuously and not limited to treating control joints in the slab. The contractor should also leave adequate space between the tile and wall to allow for expansion. These spaces can be concealed with a shoe mold or baseboard.

With so much to pay attention to, it’s important for builders to establish good long-term relationships with contractors they can rely on. Unfortunately, this isn’t always possible, especially with the current skilled labor shortage. When they do hire a new contractor, builders should carefully vet the person, asking detailed questions about how he or she will lay tile. There should also be quality assurance procedures in place to confirm that everything is being performed correctly and no steps are being skipped.

As a builder you can protect your business with 2-10 Structural Warranties, become a member today!